One of the biggest tasks is to get a crane (if the heat exchanger is located on a higher level) and the tube bundle puller machine to extract the whole tube bundle in order to reach the tube side gasket to repair it.

- Lots of resources to organize quickly to fix the leaking gasket

- It is time-consuming and labour-intensive

- A lengthy and expensive downtime

- Hopefully, the required gasket is in stock!

What if you can repair the tube side gasket without all the above hassles?

1. No need to extract the whole tube bundle out to replace the tube side gasket!

Use of metal jacketed gasket or Spiral Wound Gasket would require the tube bundle to be extracted out before you can reach to replace the damaged tube side gasket.

However, if you have a spool of SLADE Joint Sealant, you need not extract the whole tube bundle out at all.

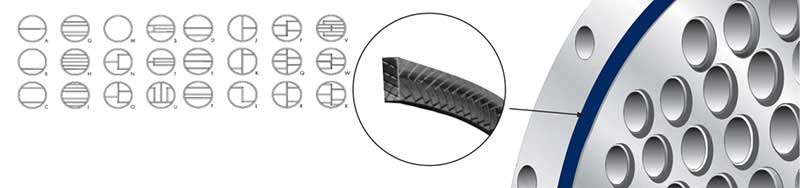

See below of how much ease to replace the heat exchanger gasket and get your heat exchanger back online quickly within one shift! Use SLADE Pyro-Tex HP Joint Sealant as an Alternative Heat Exchanger Gasket Emergency Repair Solution. You can get your heat exchanger back to service easily within one shift.

There is no need to completely pull out the tube bundle to replace the tube side gasket! Just need to slide it forward slightly to remove the damaged gasket and install it with the SLADE Joint Sealant as shown above. Once the SLADE Joint Sealant is fixed in place, tighten it up and the compression will form a homogeneous gasket in place!

2. Avoid the risks of not having the correct gasket on site!

Yes, replace all shapes and sizes of custom gaskets with one spool of SLADE Pyro-Tex Joint Sealant!

It makes a gasket of any shape and sizes on site. Upon compression, it forms a homogeneous seal!

You don’t have to carry the inventory of all the different sizes of custom gaskets sizes for each different boilers.

Benefits of SLADE Pyro-Tex HP Joint Sealant:

- High-Temperature Rating For up to 1000°C.

- Excellent for Thermal Cycling.

- High-Pressure rating up to 310 bar.

- Able to seal imperfect flange surfaces as the expanded graphite is able to flow and fill the cavities when compressed.

- Ease of installation as SLADE Joint Sealant can be simply tapped to the tube sheet according to its shape and size.

Contact Goldspark for more information on Heat Exchanger Gasket.