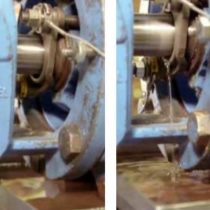

SLADE Patented Pultrusion Process enables SLADE Patented Packing Foil to be made without using additives to fuse together the carrier fibers and the fillers.

SLADE is the ONLY manufacturer that does not add additives to your packings. This breakthrough technology results in a superior product that is stronger, more durable, and has a longer service life than other packings.

SLADE Gaskets and Packing Sealing Solutions Products are protected by patents in the USA and Europe.

Adding additives has a negative effect on sealing reliability.

Read on to find out the facts.

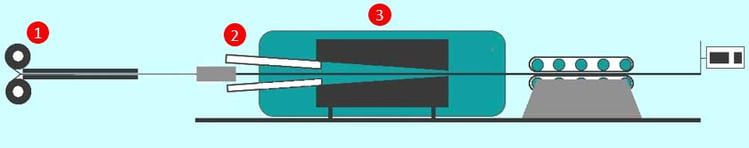

SLADE Patented Foil Pultrusion Process:

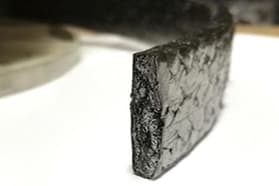

1) High Strength structural PAN Grade Carbon Fiber which is 5 times stronger than steel is pulled into the Patented machine.

2) High purity 99.26% Nuclear Grade Expanded Graphite filler is used to wrap around the above PAN Grade Carbon Fiber. Expanded Graphite is chemically inert and highly compressible! This combination is 5 times stronger than steel and offers superior properties such as chemical inertness and high compressibility.

3) The PAN Grade Carbon Fiber and the Expanded Graphite filler are securely wrapped together without the need for adhesives or additives, ensuring a high performance and long lifespan.

Experience the power of SLADE Patented Foil today!

Below is the SLADE Patented Carbon Fiber Reinforced Expanded Graphite Foil:

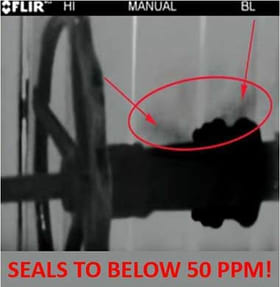

WHAT ARE THE PROBLEMS WITH ADDED ADDITIVES?

The Additives are lost during use.

The Loss of Additives will shorten the MTBR of your packings.

As the additives are lost, the packing material will not be able to tightly grip the shaft anymore. This will cause a leak path, leading to a potential catastrophic failure.

GOLDSPARK PTE. LTD.

Blk 1014, Geylang East Ave 3, #06-238, Singapore 389729

Tel: +65 8835 3702